Elastic Interface® N3XTM is an innovative 3D-printed padding specially engineered to improve the characteristics of conventional polyurethane foams and overcome their limitations, enabling cyclists to experience unparalleled levels of comfort and performance.

Thanks to N3XTM we can now control and parametrize the technical features of the padding in cycling pads with absolute precision, providing your apparel with an exclusive unique technology that focuses fully on giving your consumers what they need.

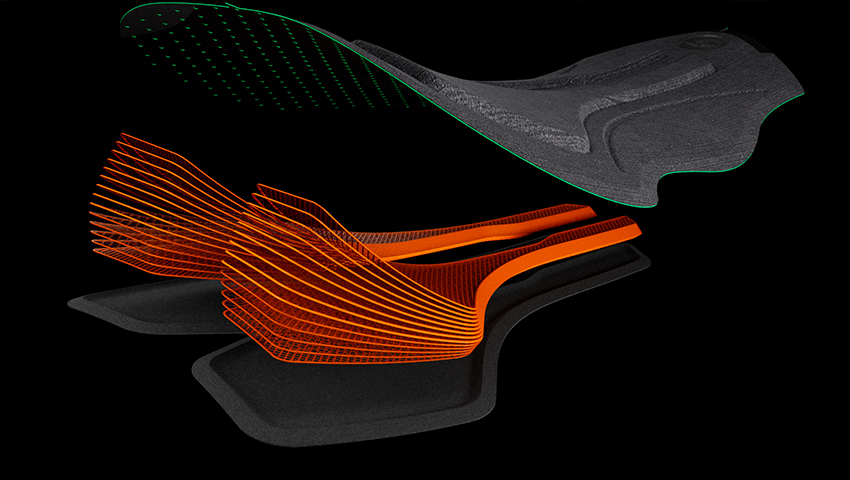

The Elastic Interface® N3XTM insert offers so many benefits, such as delivering temperature control in the sensitive pad area, ergonomic support, long-lasting, durable protection, breathability, a low-profile design, customisation and, more importantly, zero waste. Our patented 3D-printing technology gives us total control over the material’s structure.

Origins and Innovation Philosophy

The journey toward better cycling comfort took a monumental leap when Elastic Interface® first introduced elastic chamois to replace traditional leather suede. This wasn’t just a material change—it was a fundamental shift in how we approach cyclist protection and comfort.

This breakthrough marked the beginning of our relentless pursuit of innovation in cycling pad technology. Our commitment to pushing boundaries has remained steadfast over the years, culminating in our groundbreaking N3XTM technology unveiled at Eurobike 2022.

Vision and Development

N3XTM technology wasn’t born overnight. It emerged from a comprehensive analysis of existing polyurethane foam limitations. By methodically identifying specific areas where traditional materials fell short, our research team focused on creating solutions that would fundamentally transform cycling protection.

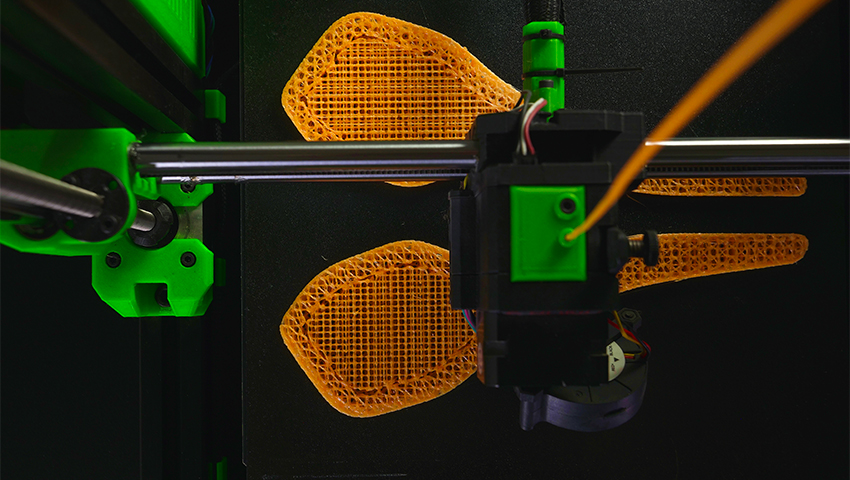

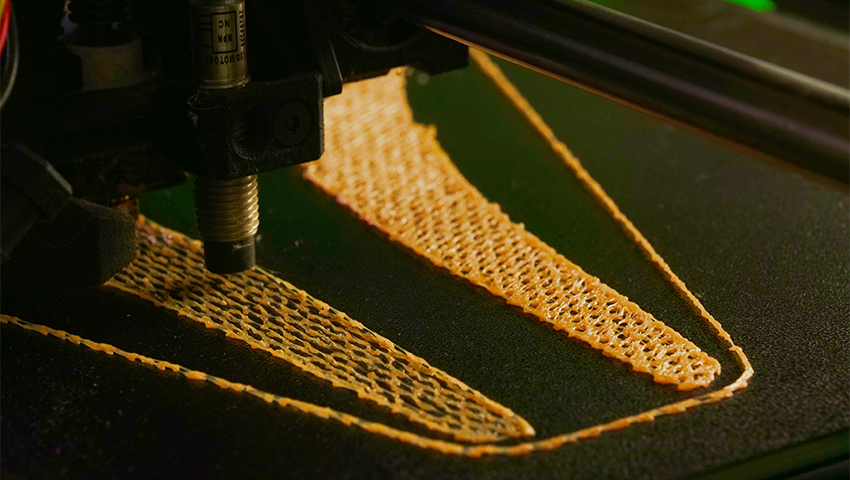

The adoption of 3D printing technology opened doors to design possibilities and functionality that were previously unimaginable in the cycling industry.

Scientific Foundation

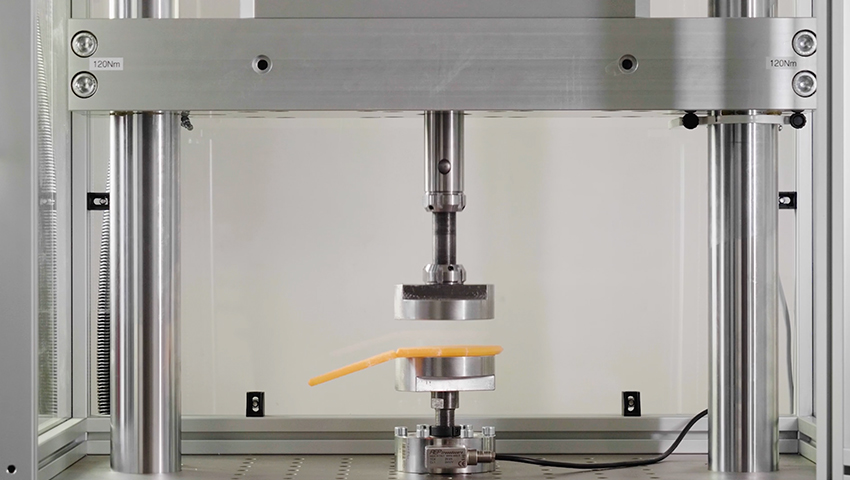

At its core, N3X technology is built on extensive research into biomechanics and material science. Our team conducted detailed studies of cyclist movement patterns, pressure distribution, and anatomical requirements across various riding styles and disciplines.

This science-driven approach ensured that our final product would address real-world cycling challenges rather than just theoretical improvements.

Engineering Excellence: The N3X Structure

The revolutionary open-cell structure of N3X represents a significant advancement in chamois design. This structure provides optimal air circulation while maintaining superior support characteristics.

Through precise control of the 3D printing process, our engineers create zones with varying densities and support levels that correspond exactly to the needs of different riding positions—something impossible with traditional manufacturing methods.

Sustainable Manufacturing

Perhaps one of the most remarkable achievements of the N3X manufacturing process is its zero-waste production methodology. The precision of 3D printing eliminates the material waste typically associated with traditional foam cutting and shaping processes.

Additionally, our use of bio-based materials aligns with modern sustainability requirements while maintaining the high-performance standards cyclists demand.

The Guarantee of an Exclusive Patented Technology

N3XTM is the culmination of years of studies, research and prototyping during which CyTech S.r.l. has built up an impressive wealth of information, not all public, about 3D printing as well as the application of this technology to pads and, more specifically, to pads that are 3D-printed to have specific technical features, providing an innovative, unique technical solution that opens up a new frontier for the cycling apparel industry.

Produced entirely with 3D-printing techniques wholly owned by CyTech S.r.l., this technology required, and still requires, considerable investments by the San Vendemiano based company. N3X TM has generated a series of intellectual protections covering suitably protected confidential information, registered models and patents for industrial inventions that create a guarantee of uniqueness and exclusivity you can only get from CyTech S.r.l.

We can now offer you the benefits of this wealth of knowledge with guaranteed safeguards and protection: you can rely on our exclusive technology, which we created to make your bib shorts even better and give them added value while greatly enhancing your customers’ in-saddle comfort and performance.

The development process yielded multiple patentable innovations, covering both unique material composition and manufacturing processes. These patents protect:

- Our specialized 3D printing methodology

- Proprietary material formulations

- Specific structural designs that optimize comfort

- Process controls ensuring consistent quality

In addition to protecting you and protecting our rights, this is exactly why we have implemented strict market controls designed to detect and combat any counterfeits if and when they should arise.

As always, our sales division is only too happy to help should you have any queries or enquiries.

Industry Collaboration

The cycling industry has recognized the transformative potential of N3X technology, leading to partnerships with several premium brands. These collaborations demonstrate the technology’s versatility and its ability to meet the exacting standards of professional cycling equipment manufacturers.

Future Development

Through these partnerships, N3X technology continues to evolve, incorporating feedback from professional athletes and everyday cyclists alike. This collaborative approach ensures that the technology remains at the forefront of cycling comfort innovation, with ongoing developments in materials and manufacturing processes.

As we look to the future, we see N3X technology as just the beginning of a new era in cycling comfort. The third dimension of comfort isn’t just about adding another layer—it’s about reimagining what’s possible when innovation, science, and passion converge.

Join us on this journey as we continue to transform the cycling experience, one revolutionary innovation at a time.

To learn more, click on the page dedicated to N3X technology.